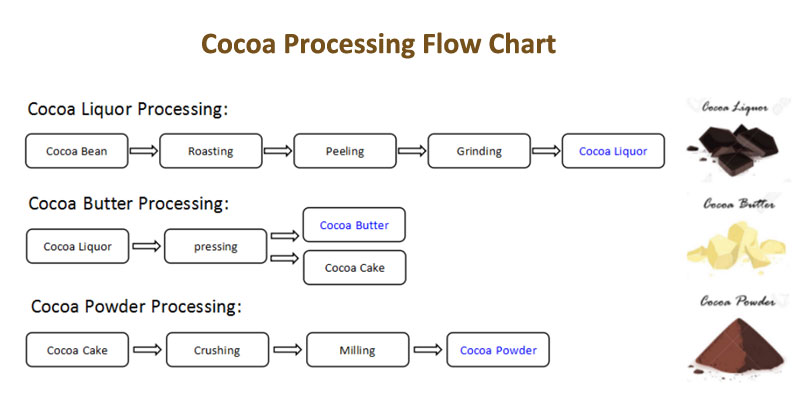

Cocoa beans are an important economic crop and are also divided into many varieties with different flavors. There are four main products of cocoa beans after processing: cocoa nibs, cocoa liquor, cocoa butter, and cocoa powder. Today, let us approach the cocoa factory and take a look at the cocoa processing flow chart.

Process Flow of Cocoa Beans:

Cocoa beans — stone removal — roasting — peeling — picking — sauce grinding (cocoa liquor) — oil extraction (cocoa butter) — crushing — powdering (cocoa powder)

1. Roasting and Peeling Cocoa Beans – Cocoa Nibs

After cocoa beans are roasted at a special temperature, the Maillard reaction occurs, resulting in a fascinating aroma. As the roasted cocoa beans cool, the skin becomes hard and crispy and can be easily removed. After peeling, cocoa nibs are obtained.

Use a professional cocoa bean roaster to achieve continuous production and constant temperature control. While realizing automatic production, the flavor of the finished cocoa beans is also guaranteed. The special cocoa bean peeling equipment used has a peeling rate of more than 95%, and is corrosion-resistant and has a long service life.

2. Grinding Cocoa Nibs – Cocoa Liquor

Then the cocoa nibs are ground, and the cocoa nibs become small particles, which are more conducive to the extraction of cocoa butter.

Cocoa nibs are ground using a colloid mill. In the process of grinding the sauce, the large particles of cocoa crumbs will become particles of only about 0.15mm under the high-speed shearing and friction of the colloid grinding rotor, and the efficiency is very high.

3. Pressing Cocoa Liquor – Cocoa Butter

Cocoa paste is pressed under high pressure so that we can extract cocoa butter.

The cocoa butter is pressed using a hydraulic press. First, put the cocoa paste into a press filter bag, and press it under high pressure. In just 10 minutes, the oil content in the cocoa cake can reach about 12%. We get brightly colored cocoa butter.

4. Crushing and Grinding – Cocoa Powder

The cocoa cake remaining after pressing is crushed twice to obtain cocoa powder.

The filter cake taken out is coarsely crushed using crushing equipment. Then, we use a finely pulverized equipment-cocoa mill to grind, the whole 201 of the machine, and finally obtain cocoa powder with uniform particles. The fineness of cocoa powder can be adjusted through an adjustable mesh screen.

Cocoa powder has a strong cocoa aroma, is a nutrient-rich food, not only contains high-calorie fat, but also rich in protein and carbohydrates. Cocoa powder also contains a certain amount of alkaloids, which have the functions of dilating blood vessels and promoting human blood circulation. Eating cocoa products is beneficial to human health.

The above is the introduction of the cocoa processing flow chart, and also introduced some cocoa processing machines. If you want to know more about cocoa processing, please contact us.

Email: [email protected]

WhatsApp/Mobile: +8615515597212

We are looking Quotations for Cocoa processing Line as following:

1. COCOA LIQUOR PROCESSING .

2. COCOA BUTTER PROCESSING.

3. COCOA POWDER PROCESSING.

Hi,

Glad to receive your message.

1. In which country is the machine used?

2. How many kilograms of cocoa beans do you want to process per hour?

I also sent an email to your email address, please check it.

Waiting for your reply.

Best Regards,

Serena

Email: [email protected]

Whatsapp/Mobile: +8615515597212