Cocoa powder has a strong cocoa aroma and is widely used in the production of cocoa-containing foods, such as chocolate, drinks, milk, ice cream, candies, pastries, etc.

How is Cocoa Powder Made?

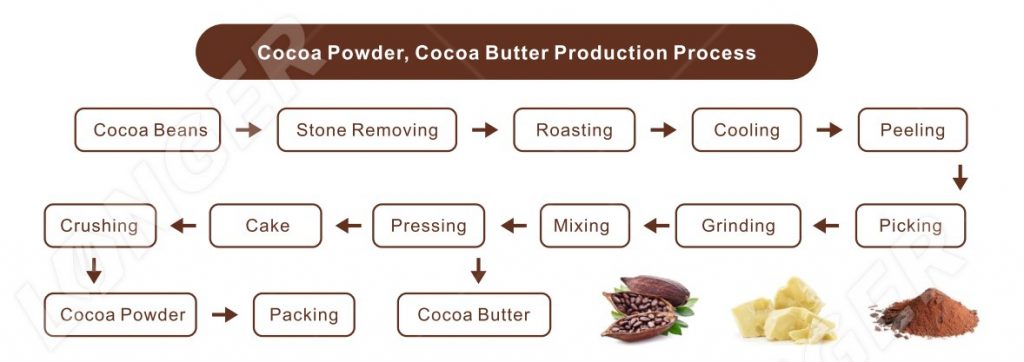

Cocoa beans are transported from the cocoa planting area to the chocolate factory. After cleaning, roasting, winnowing, crushing, grinding and pressing, they can be processed into three products: Cocoa Mass or Cocoa Liquor, Cocoa Powder, Cocoa Butter.

How Cocoa Powder is Made in Factory?

- Cleaning and selection: removing sand and stones in cocoa beans, and selecting and removing unqualified and spoiled beans, so as to ensure the quality of finished cocoa powder.

- Roasting: This is an important step for the rich cocoa flavor. Cocoa beans are heated and roasted at a high temperature of 100 to 120 degrees, and the whole process takes 30 minutes.

- Peeling: After roasting, the cocoa beans cool quickly. Then the crispy thin shell of the cocoa beans is removed, and the cocoa beans are crushed into nibs.

- Grinding sauce: In the factory, we use a sauce grinder, which can directly grind the cocoa nibs into cocoa sauce, and then condense into blocks after cooling, called cocoa liquor. The fat content is above 50%, and there are other complex ingredients.

- Oil extraction: Cocoa butter can be obtained by pressing cocoa liquor, which becomes a raw material for the production of chocolate.

- Crushing: After the cocoa liquor is squeezed to remove the oil, the cocoa cake is retained, which is then crushed and ground to obtain cocoa powder.

Cocoa Powder Production Line in the Factory:

- Cocoa Bean Roasting Machine (Belt Type):

Continuous roasting equipment, heating device and thermal circulation device make uniform circulating hot air in the oven, and the color of the roasted material is uniform without damage. Automatic temperature control. - Cocoa Bean Peeling Machine:

The cocoa beans are crushed by rubber roller squeezing and differential rubbing, while the centrifugal fan sucks the skin out. high productivity. - Cocoa Liquor Grinding Machine

This machine is a machine for fine grinding of fluid materials, which can be effectively emulsified, dispersed, homogenized and crushed. The main parts are made of stainless steel, which is corrosion resistant. - Cocoa Butter Press Machine:

The hydraulic oil press achieves the effect of oil output through the pressing force of the hydraulic cylinder. High hardness, high strength, good wear resistance, suitable for high temperature and high pressure continuous operation.

Click to rate this post!

[Total: 0 Average: 0]