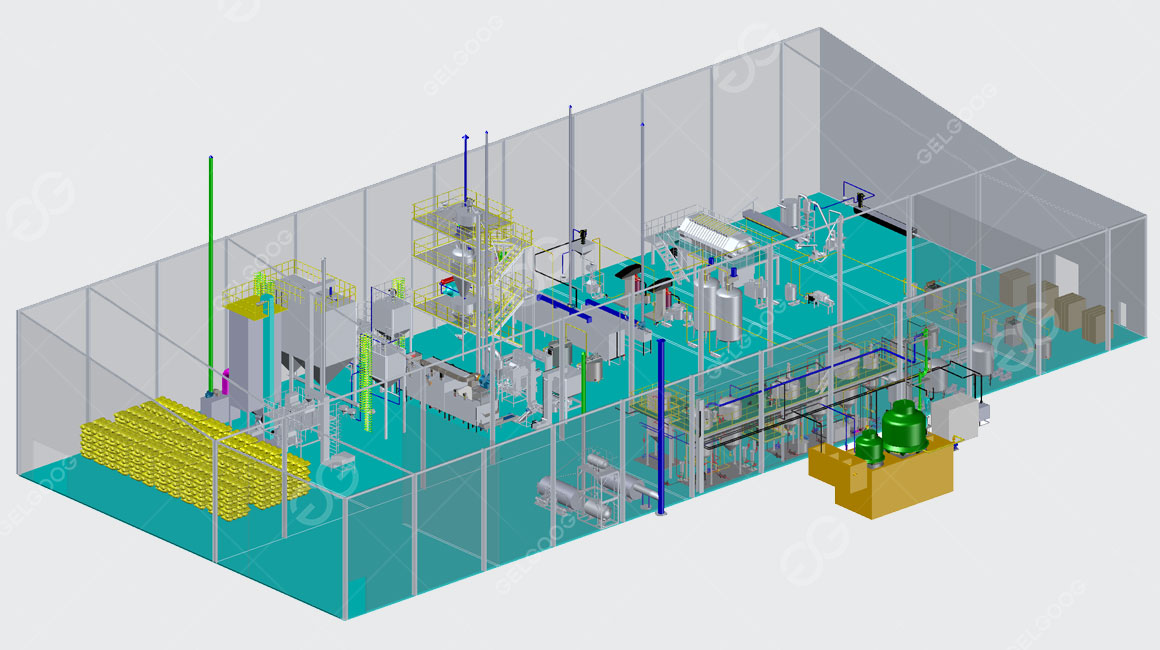

Cocoa Powder Production Line

With the vision of “becoming a trusted brand in the food industry”, we are always driven by innovation and deeply integrate cutting-edge technology with craftsmanship. Our carefully crafted cocoa powder production line is committed to redefining industry standards and creating sustainable core value for customers.

- Intelligent pretreatment system: using advanced screening and cleaning technology to automatically remove impurities in cocoa beans, accurately control the moisture content, and lay a solid foundation for the production of high-quality cocoa powder; with intelligent temperature control baking system, it can flexibly adjust the baking curve according to different cocoa bean varieties and customer flavor requirements to stimulate unique aroma and mellow taste.

- Intelligent alkalization: using an integrated alkalization intelligent control system, the alkalization process parameters can be freely switched for different cocoa raw materials, saving time for switching materials and improving the production efficiency of the entire line.

- Precision grinding and pressing: using nano-level grinding technology, the cocoa beans are ground to a golden particle size of 20-75μm, giving the powder a silky smooth touch; through the intelligent cocoa hydraulic pressing system, the content of cocoa butter in the powder can be freely customized in the range of 10%-35%. Whether it is high-fat powder for high-end baking or low-fat powder for healthy drinks, it can be produced on demand and accurately meet market demand.

- Fully automated intelligent control center: From raw material feeding to finished product packaging, the whole process can be unmanned. The abnormal production process will automatically trigger the early warning and correction mechanism to ensure the consistent flavor of the products produced by the production line.

- Flexible capacity adjustment platform: Modular design breaks the capacity boundary. Through the “module” equipment combination, it can achieve a free combination of 12 tons to 100 tons per day. Whether it is small-batch customization of boutique workshops or large-scale production of industrial giants, the efficiency can be maximized with the optimal configuration.

Choosing our cocoa powder production line is to choose to go with the industry’s cutting-edge technology. Drive industrial upgrading with the power of intelligent manufacturing and build a commercial future with the foundation of quality. Let us work together to open the golden age of the cocoa industry!

Cocoa Powder Production Process

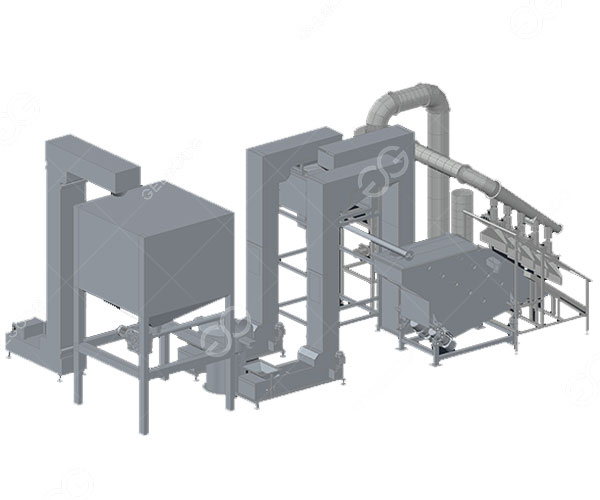

Cocoa Bean Metering & Roasting

Precisely control the amount of raw materials input to ensure the uniformity of the roaster input; the roasting system adopts a double air chamber structure and multi-stage roasting technology, and can flexibly adjust the roasting temperature and time for different varieties of cocoa beans to ensure that the cocoa beans produce a pleasant aroma after roasting.

Roasting machine output range: 100-4000kg/h

Cocoa Bean Crushing & Winnowing

After pre-treatment, the cocoa beans enter the shelling process. The system crushes, grades, and winnows the cocoa beans to produce cocoa nibs with a shell content of ≤2%. A high shelling rate is the key to ensuring the quality of the final cocoa powder.

Raw material processing range: 500-1500kg/h

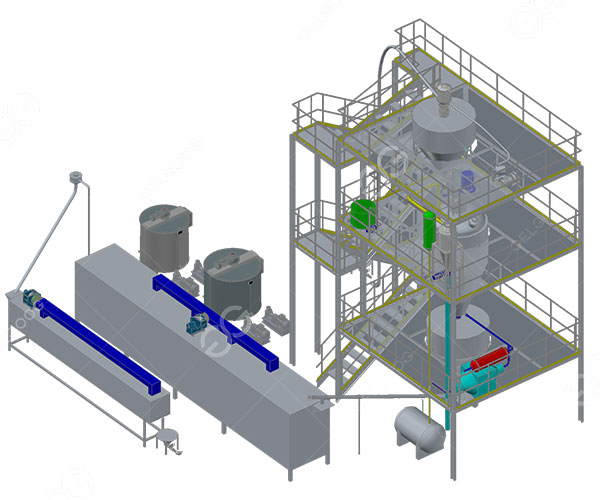

Cocoa Bean Sterilization & Alkalization

The Dutch alkalization process is currently the most mainstream alkalization process. By adjusting the temperature, time, alkali solution, etc., different pH values and color changes can be achieved. After alkalization, it can produce a richer and more pleasant aroma. The alkalized cocoa powder obtained after this process has expanded its scope of use and created more commercial value for you.

The system is fully automatically controlled and can adjust the alkalization parameters of different varieties of raw materials. At the same time, it can be equipped with small batch experimental equipment to shorten the adjustment time of changing raw materials and improve work efficiency.

Raw material processing capacity: 300-3000kg/batch

Cocoa Liquor Grinding

After pre-grinding and refining, cocoa nibs become cocoa paste, reaching the preset paste fineness. Not only can it be used directly for filling, but also for further processing. The system can automatically control the temperature to avoid the impact of high temperature on the flavor of cocoa paste.

Production range: 250-2000kg/h

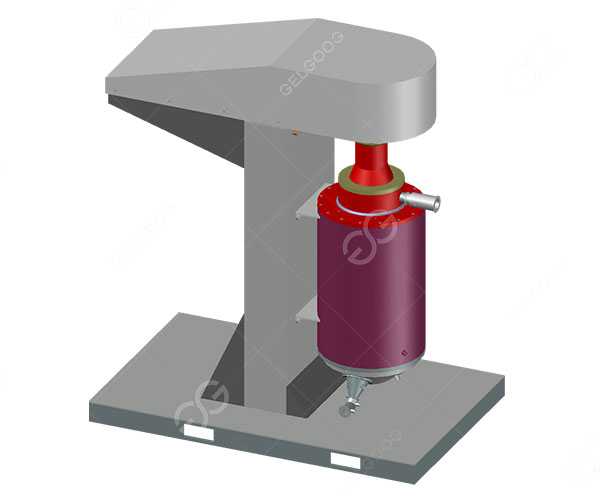

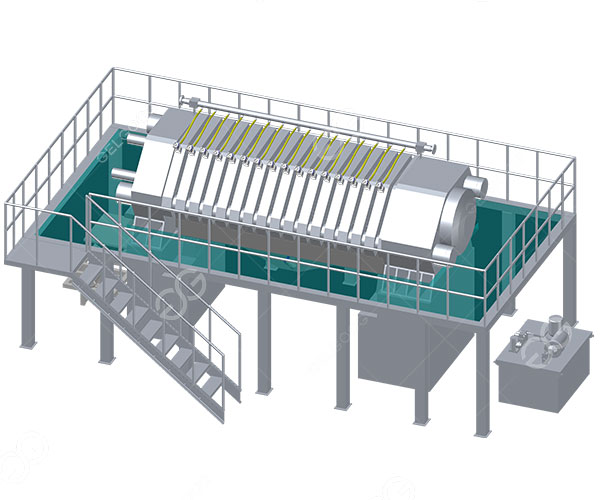

Cocoa Butter Pressing

In the cocoa liquor presses, the butter is separated from the cake. The total pressing cycle can divide in 3 main steps :filling, pressing, discharging. The cocoa cake is crushed by a crusher. After crusher the cake size ≤15mm.

The system is a pure physical pressing form, which can maximize the natural flavor of cocoa powder; it adopts fully automatic control logic to realize automatic feeding and discharging, meets the use requirements of HACCP, and avoids the generation of biological hazards.

Cocoa butter pressing output: 100-1500kg/h

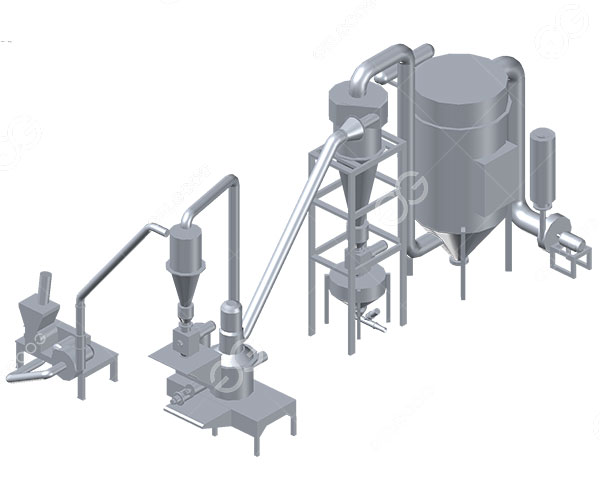

Cocoa Powder Grinding

After the cocoa cake is crushed, it passes through the grinding system to obtain 200-mesh cocoa powder.

The system is equipped with a temperature control system to reduce the temperature of the material during grinding. At the same time, it is equipped with a cocoa powder cooling system to effectively prevent the cocoa powder from agglomerating during storage.

Output of a single device: 50-800kg/h

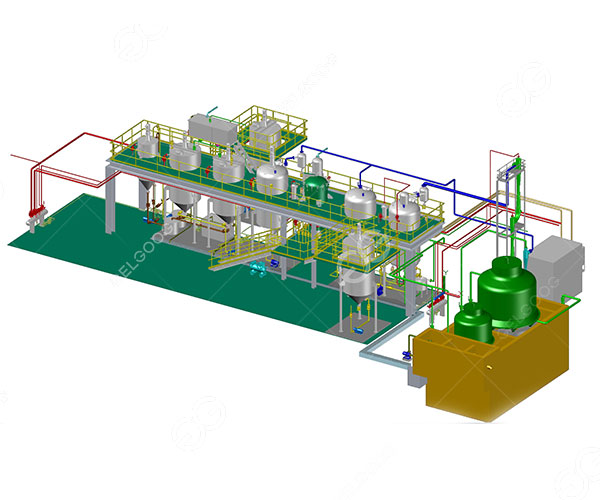

Cocoa Butter Deodorization

The obtained cocoa butter has a high content of free fatty acids, and the cocoa butter obtained after the alkalization process has a high content of soap. Excessive content of this substance leads to poor taste and flavor of the product. In order to remove such substances, the deodorization process can obtain products with better flavor and color, and broaden the use of the product, helping you to obtain higher commercial value.

Deodorization system output: 200-50000 kg/day

Cocoa Powder Production Video

Customized Cocoa Solution Output Range

No. | Solution Name | Capacity Range | Automation Level | Final Products |

1 | Natural & Alkalized Cocoa Processing Line | 100–300 kg/h | Semi-automatic & Full-automatic | Cocoa nibs, cocoa liquor, cocoa butter, natural & alkalized cocoa powder |

2 | Natural & Alkalized Cocoa Processing Line | 500 kg/h | Semi-automatic & Full-automatic | Cocoa nibs, cocoa liquor, cocoa butter, natural & alkalized cocoa powder |

3 | Natural & Alkalized Cocoa Processing Line | 1000 kg/h | Full-automatic | Cocoa nibs, cocoa liquor, cocoa butter, natural & alkalized cocoa powder |

4 | Natural & Alkalized Cocoa Processing Line | 1500 kg/h | Full-automatic | Cocoa nibs, cocoa liquor, cocoa butter, natural & alkalized cocoa powder |

5 | Natural & Alkalized Cocoa Processing Line | 2000 kg/h | Full-automatic | Cocoa nibs, cocoa liquor, cocoa butter, natural & alkalized cocoa powder |

6 | Natural & Alkalized Cocoa Processing Line | 4000 kg/h | Full-automatic | Cocoa nibs, cocoa liquor, cocoa butter, natural & alkalized cocoa powder |

Our company has rich design and commissioning experience in the field of deep processing of cocoa beans. We can flexibly customize the production line according to the user’s requirements to meet the production and budget requirements of different users.